Common gas monitoring applicatons in the industrial safety sector include:

Industrial environments often contain hazardous gases that can pose serious health risks to workers. Gas monitoring systems continuously monitor the air for toxic and explosive gases, providing an early warning of dangerous conditions and allowing workers to evacuate or take appropriate safety measures.

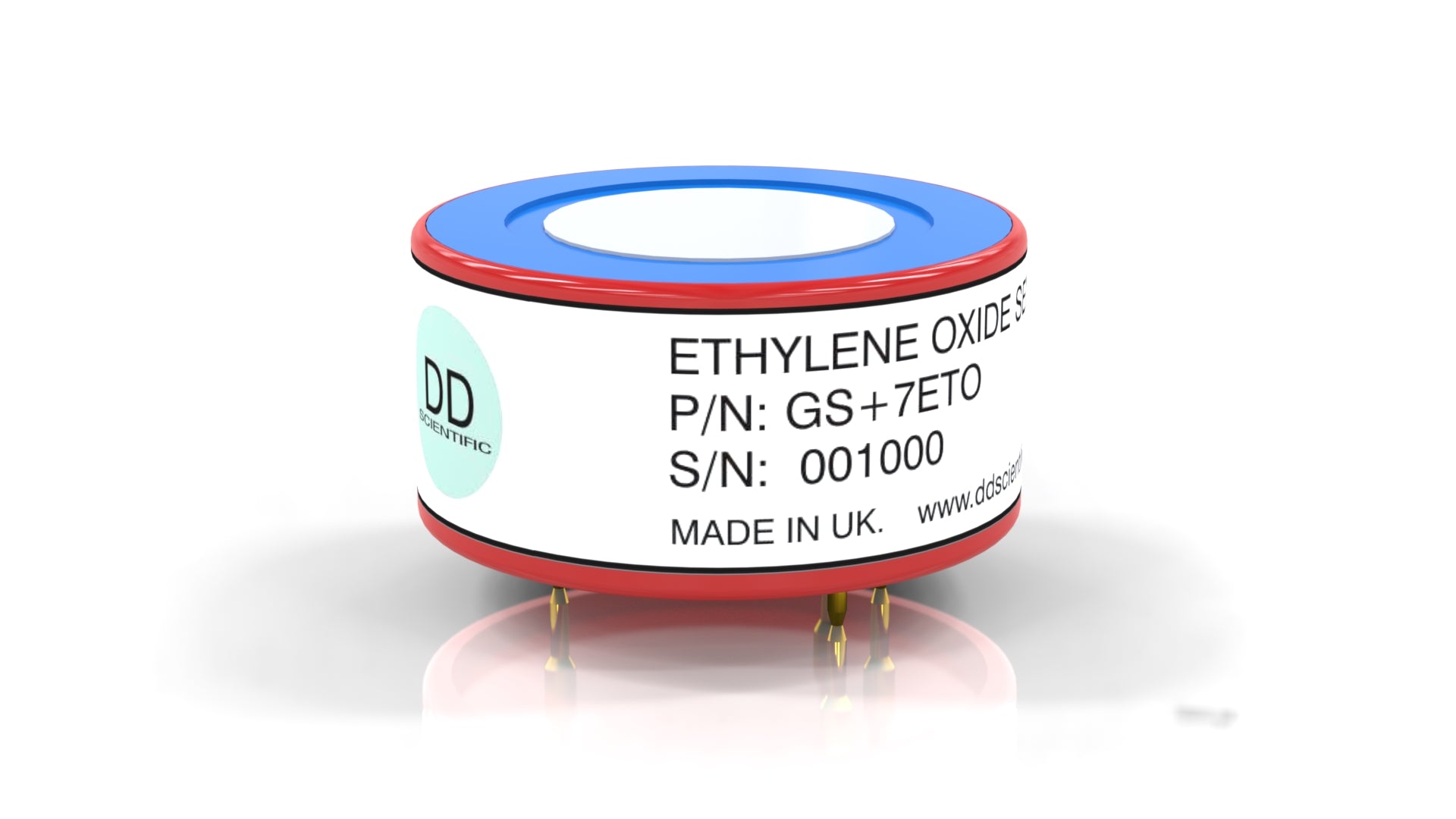

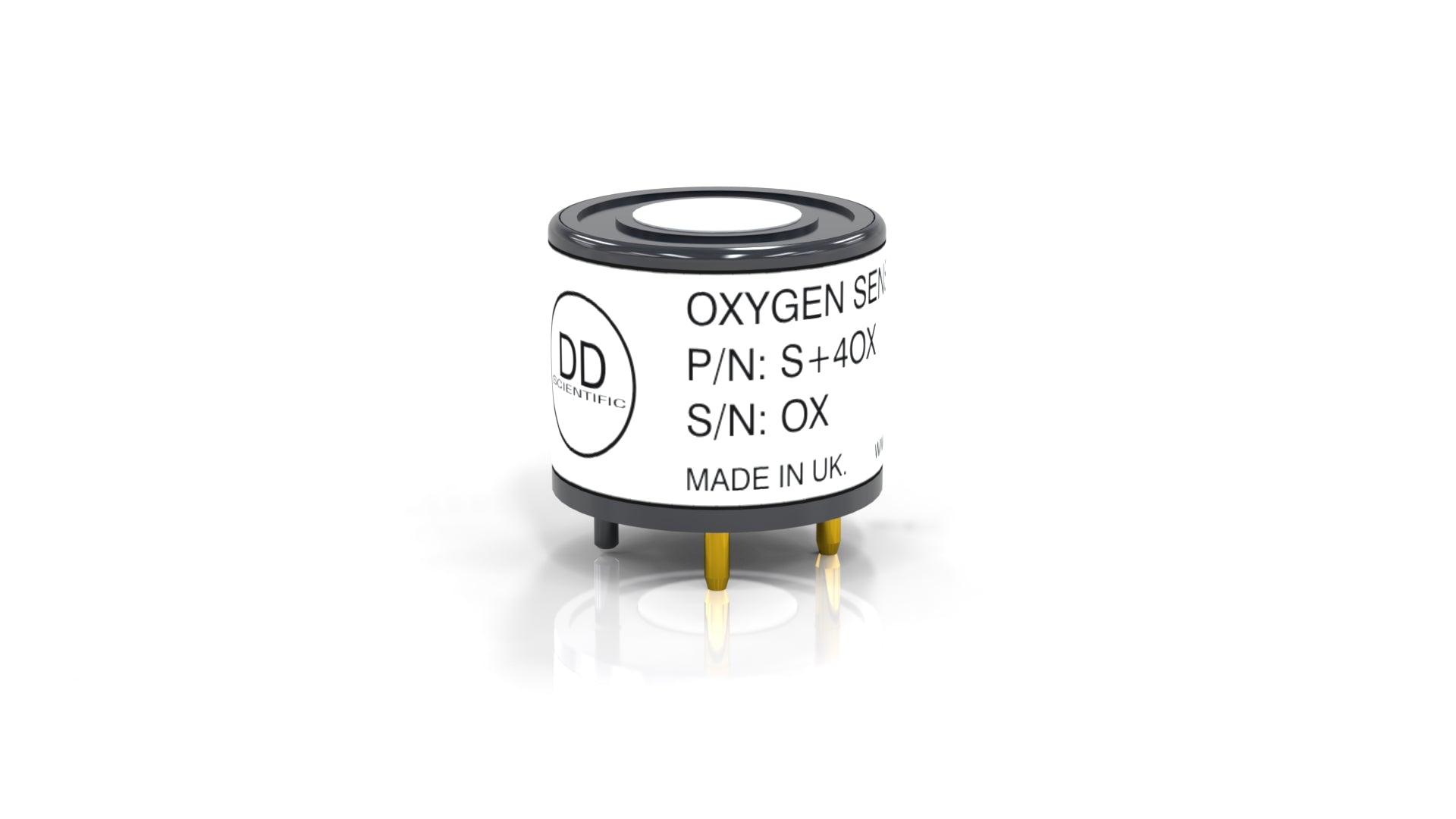

Confined spaces, such as tanks, vessels and trenches, present unique safety challenges due to limited ventilation and potential gas accumulation. Gas monitoring is essential for assessing confined space atmospheres and ensuring that workers can safely enter and work in these environments. Monitoring for gases such as Oxygen (O2), combustible gases such as Methane (CH4) and toxic gases like Carbon Monoxide (CO) and Hydrogen Sulphide (H2S) helps prevent asphyxiation, explosions, and poisoning incidents.

In the event of a gas leak, fire, or other emergency, gas monitoring systems play a critical role in facilitating emergency response efforts. Real-time monitoring of gas concentrations enables rapid detection of hazardous conditions, triggering alarms to alert workers and emergency responders and guiding evacuation and mitigation efforts to minimise the impact of the incident.

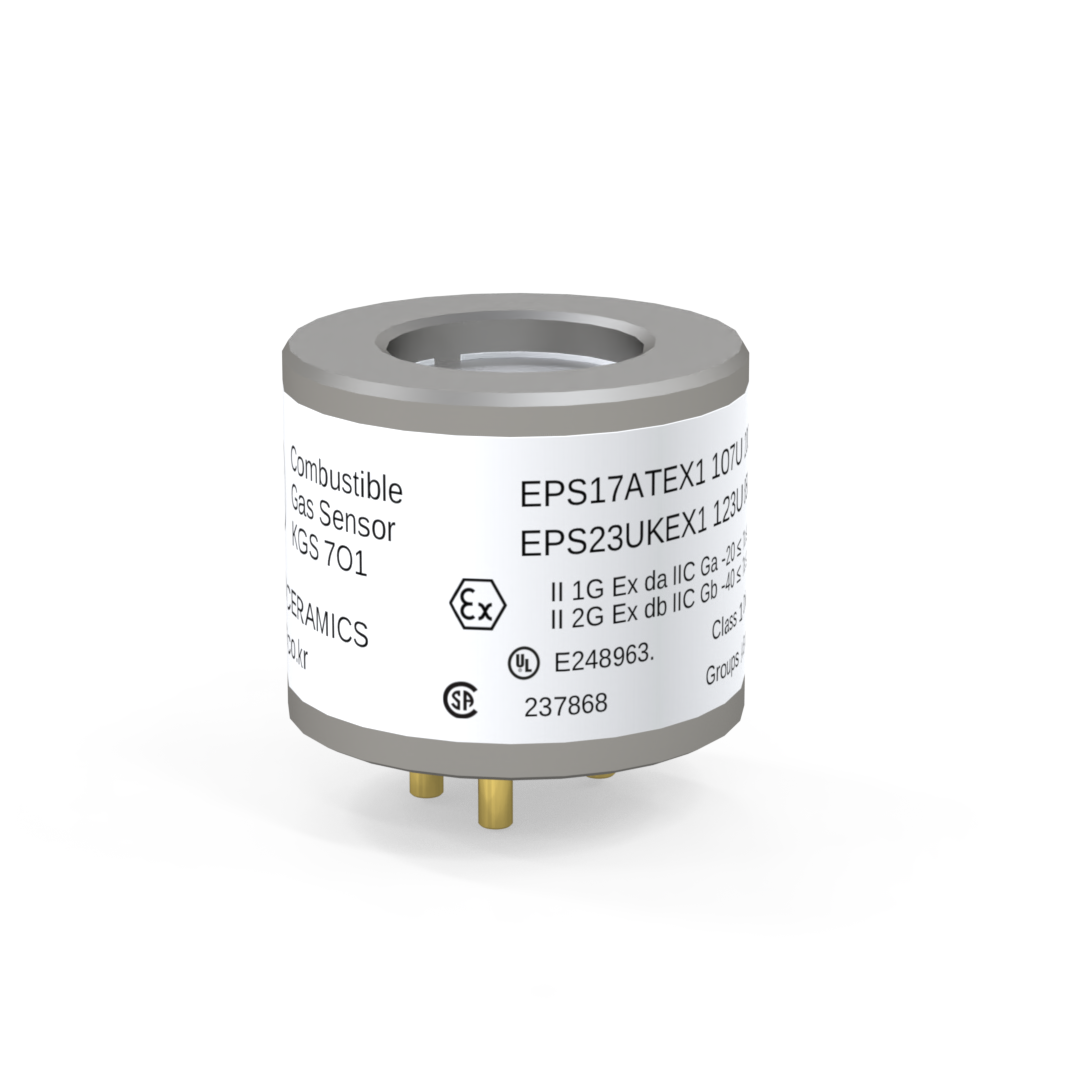

Gas monitoring is an integral part of process safety management systems, helping industries identify and mitigate risks associated with their operations. By monitoring gases such as CH4, Propane (C3H8) and Hydrogen (H2) in process areas, industries can detect leaks, monitor process conditions, and implement control measures to prevent accidents and ensure safe operation of equipment and facilities.

Gas monitoring data informs the selection and use of personal protective equipment (PPE) for workers exposed to hazardous gases. By accurately assessing gas concentrations in the work environment, employers can provide appropriate respiratory protection, such as gas masks or respirators, to ensure worker safety and compliance with occupational health and safety regulations.

Legislation governing gas safety varies by country and region however most stipulate the needs for monitoring of a wide range of potentially hazardous gases. In the US, Occupational Safety and Health Administration (OSHA) standards and the Clean Air Act regulate hazardous gas handling and monitoring. Europe has directives such as the Control of Major Accident Hazards (COMAH) and the Control of Substances Hazardous to Health (COSHH) Regulations in the UK. China has regulations under the Work Safety Law. These laws are intended to ensure the safe handling, monitoring and control of hazardous gases, protecting public health, worker safety and the environment.

Industrial Safety Sensors Application Support

We work with a broad range of customers in the Industrial Safety Sensors sector and will be glad to discuss your specific needs, be it integration of DDS sensors or outlining the benefits our sensors can bring to your instruments.

To talk to one of our application specialists get in touch today.