Quality at DD-Scientific

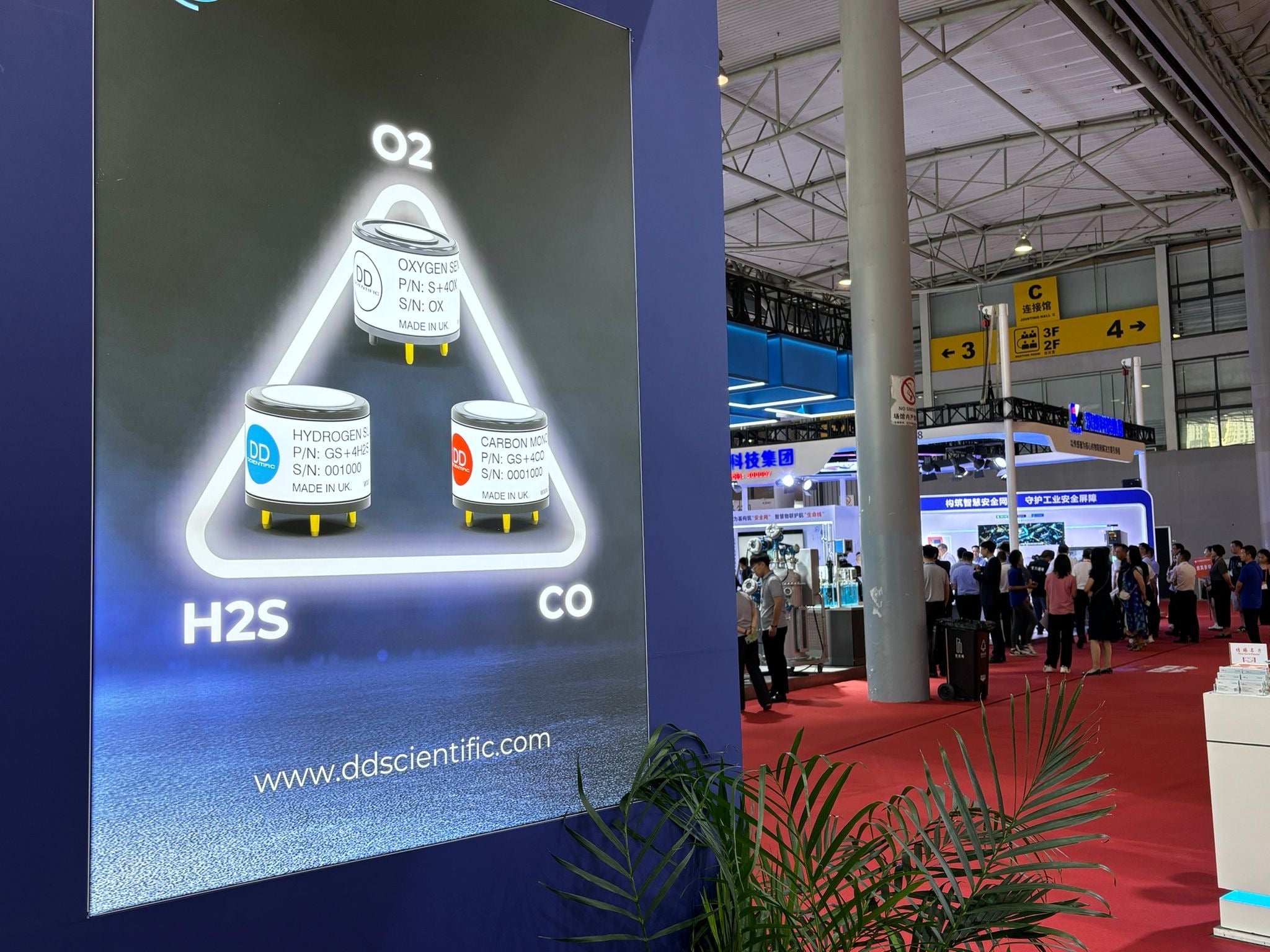

At DD Scientific we are proud to be the Worlds' leading high-volume manufacturer of high-quality electrochemical gas sensors.

Our pragmatic and customer-focused approach to excellence is underpinned by adherence to the international standard ISO 9001:2015 for quality management and UL2075 for performance standards.

Our commitment to quality sees us validate the performance of every sensor we manufacturer prior to despatch. We do this using our state-of-the-art, high-volume automatic test system (ATS), a rigorous test and validation procedure which employs a number of test processes, some of which are unique to us, to ensure our products meet specification.

Our continued dedication to excellence ensures we consistently deliver reliable, environmentally responsible, and high-performing products which not only meet but frequently exceed customer expectations.

⬇️ Below you will find an overview of our testing procedures and policies. If you need more specific information relating to quality or production please contact us.

The most rigorous of testing

We supply to many of the World's biggest manufacturers of safety instruments and understand the criticality of sensor performance to those customers and end users alike.

We also understand the cost of poor sensor quality, whether it manifests itself in from production or the field.

Our goal is for 100% customer satisfaction and that means 100% sensor performance. Its for this reason that we employ what we believe are the most rigorous testing procedures in the industry.

Prior to release, our sensors are tested vs specification to the following methods/criteria;

Oxygen Sensors - Lead and Lead-free variants

- Output in air

- Output in nitrogen (baseline)

- T90 response time

Additionally, for 4OX and 4OX3 we also measure the sensors’ response and recovery to a 60mm H2O equivalent pressure transient.

Oxygen Sensors - partial pressure type

- Output in air

- Output in nitrogen (baseline)

- T95 response time

- Linearity - comparison between output in air (20.9% O2) and 100% O2.

Toxic Sensors

- Baseline (output in air)

- Sensitivity (output in target gas)

- T90 response time

Additionally, for sensors which are low H2 cross-sensitivity, we test this cross sensitivity test with hydrogen to ensure adherence to specification.

For Dual Toxic sensors we also measure the cross sensitivity of each channel to other target gas - i.e. CO sensitivity on H2S channel and vice versa.

All sensor test data is retained and can be provided to customers upon request.

The quality standards we work to

ISO 9001:2015 - Quality Management Systems (QMS)

Purpose: To ensure consistent product quality and enhance customer satisfaction.

Key Components:

- Leadership: Commitment from top management to ensure effective implementation of the QMS.

- Risk-Based Thinking: Identifying and addressing potential risks and opportunities.

- Customer Focus: Ensuring customer needs and expectations are met.

- Process Approach: Managing activities as interrelated processes that function as a coherent system.

- Continuous Improvement: Ongoing efforts to improve processes, products, and services.

- Performance Evaluation: Regular monitoring, measurement, analysis, and evaluation of QMS performance.

UL 2075 - Standard for Gas and Vapor Detectors and Sensors

Purpose: To ensure the safety and reliability of gas and vapor detection systems.

Key Components:

- Safety Requirements: Ensuring detectors and sensors meet performance and reliability standards.

- Performance Testing: Conducting rigorous tests to verify detection accuracy, response time, and durability.

- Environmental Testing: Assessing the impact of environmental conditions (temperature, humidity, etc.) on device performance.

- Electrical Safety: Ensuring compliance with electrical safety standards to prevent hazards.

- Marking and Documentation: Proper labelling and providing comprehensive documentation for installation and operation.

Need our help?

If you need assistance selecting, sourcing or integrating one of our sensors we are here to help.