Environmental

With our manufacturing facility situated on the South Coast of the UK, adjacent to the historic medieval Portchester Castle and between the South Downs National Park and the Isle of Wight UNESCO Biosphere reserve, we are acutely aware of our impact locally as well as on a Global scale.

As a business we are committed to minimising our environmental footprint as far as possible and sustainability is at the core of our operations.

We regularly review our practices to ensure we are mindful of the need to protect and preserve our planet and work collaboratively with our customers to ensure our environmental policies have maximum impact.

♻️ Some of the steps we are taking to become more environmentally responsible are outlined below.

Product Development

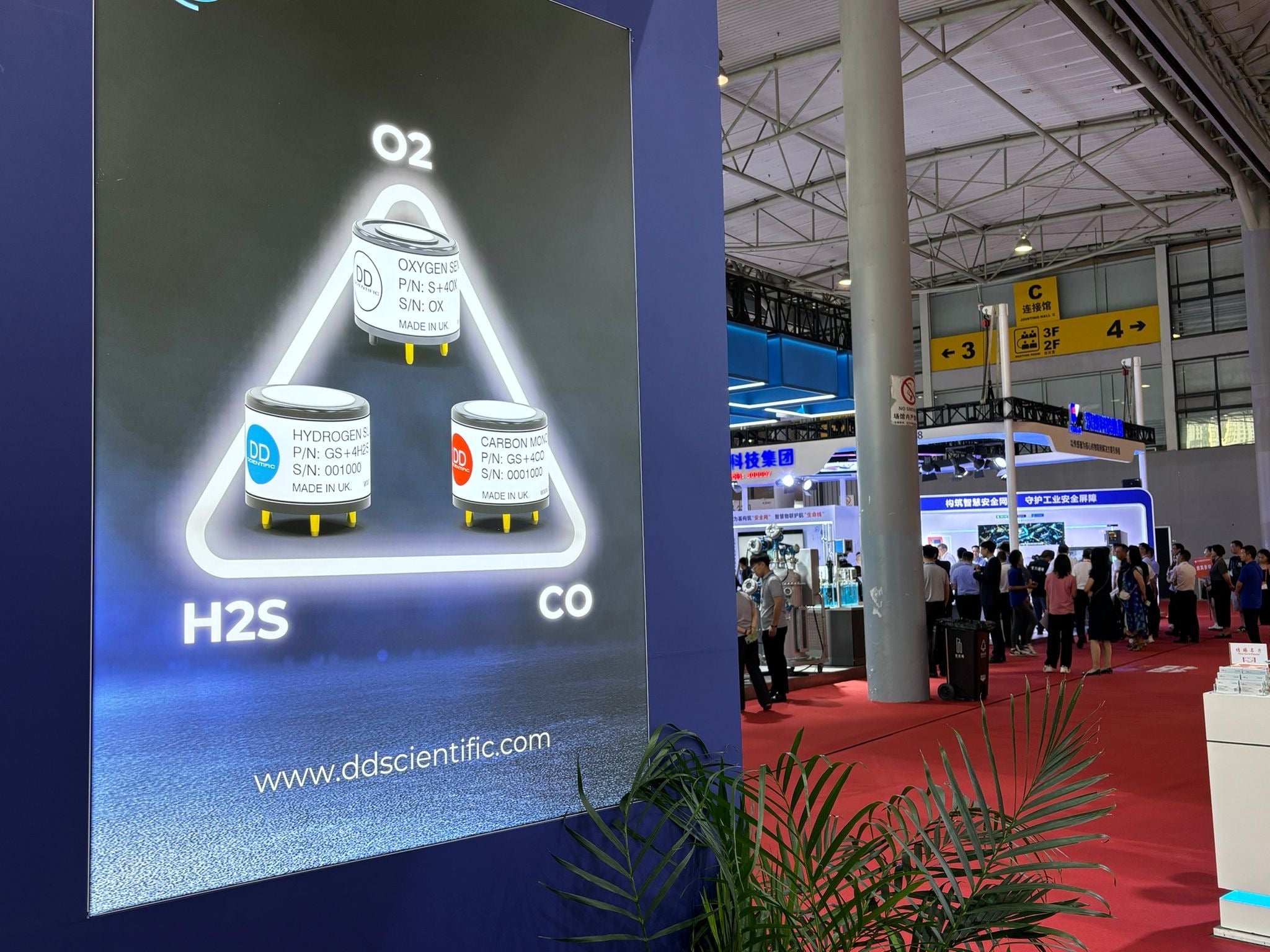

With the largest OEM gas sensor manufacturing facility in the World, we have the opportunity to steer the future of our industry in a greener direction. A primary example of this is the pioneering Lead-free O2 sensor we launched in 2019, more details of which can be found below.

We look forward to contributing further to environmental progress with the introduction of our new range of 4-Pin PPB Air Quality sensors. This will provide the industry with a premium environmental sensor which thanks to our advanced automation will be pitched at a significantly reduced price compared to similar products. Its through this kind of innovation in design and manufacture that we bring better products to market at lower price points, in the case of our PPB range, contributing to the democratisation of air quality monitoring for the greater good.

Material Reduction

We work hard to reduce material usage in our products through the use of innovative design and manufacturing techniques which avoid the need to compromise on quality or performance.

Material reduction in manufacturing minimises waste, conserves resources and reduces energy consumption. It also decreases the environmental impact associated with extraction, processing, and transportation of raw materials.

In addition to the environmental benefits of material reduction, our costs are reduced, allowing us to present our customers with a significantly better value proposition than other sensor manufacturers.

Lead-free O2 Sensors

Traditionally, electrochemical O2 sensors relied on the presence of lead in their construction. The use of lead however, potentially poses both environmental and health risks. In 2019, in response to this industry wide challenge, DDS launched a pioneering range of lead-free sensors which for the first time provided instrument manufacturers with a true alternative to lead.

In developing these innovative new sensors, we eliminated the environmental and health hazards associated with lead and enabled instrument OEMs to comply with RoHS regulations, promoting a safer workplace and reducing hazardous waste. Additionally, DDS lead-free sensors offer improved durability and performance vs lead-based sensors, ensuring fast and accurate oxygen measurements whilst reducing industrial waste thanks to a lifetime of more than 3 x that of their lead-based predecessor.

The transition to lead-free sensors is a journey that increasingly more OEMs are undertaking in new product development and one we are happy to support our customers with.

Sustainable Packaging & Recycling

We actively reduce the environmental impact of our packaging by using recyclable and biodegradable materials. In selecting eco-friendly packaging options, we ensure that our products arrive safely while being kind to the planet.

Recycling is a fundamental part of our environmental strategy at DD-Scientific where comprehensive recycling programs ensure that materials such as paper, plastics and metals are efficiently recycled. In many cases, we work collaboratively with our customers to reuse packaging and recycle used and expired sensors.

In reducing waste and reusing materials where possible, we minimise our impact on landfills, contribute to a more sustainable future and make financial savings which enhance our overall value-proposition.

Green Travel Initiatives

We have taken a number of steps to reduce the carbon footprint of our business travel at DD-Scientific.

Key to this was transitioning the DD-Scientific company car fleet to 100% electric vehicles which was finalised in 2023. In support of this we have multiple electric chargers onsite at our factory which are accessible both to company car drivers and visitors. Additionally, we encourage car sharing where possible for company travel which has both economic and environmental benefits.

Global travel is essential to us doing business however we limit air travel to essential visits meaning we only fly when we really need to and we make the most of our time overseas with multiple meetings on the same trip.

Need our help?

If you need assistance selecting, sourcing or integrating one of our sensors we are here to help.