Our Story

Since our founding in 2011, we have remained committed to the development of high-quality, reliable and cost-effective electrochemical gas sensors that help improve health, safety and efficiency across a multitude of industries.

From humble beginnings, we have evolved to become a global leader in the gas sensor industry. With a talented team of industry experts and a state-of-the-art manufacturing facility, we continue to push the boundaries of possibility in gas sensor development.

Join us as we look back on some of our milestones as well as looking forwards to some of the exciting developments we have in store.

The Story begins....

In April 2011, founder and CEO Daniel Davies registers DD-Scientific for the first time, fuelled by a vision of becoming the No.1 global gas sensor supplier.

With 10+ years experience in sensor development and a 500 ft2 facility in Havant, Hampshire, Daniel commences immediately with the development of an innovative new range of gas sensors.

The first DD-Scientific sensor comes to market

Opening the portfolio with a new design of Lead-Oxygen sensor, DDS go to market in Europe. Innovative design and extensive cost-engineering put the DDS product at an entirely new price point in the sector. The new product gains traction immediately.

Asia export commences

Partnering with industry acquaintance and friend 木易 Stone, export to China begins via Sandat Electronics. This marks the beginning of longstanding relationship and Stone remains a key partner and member of the DDS family to this day.

Moving with the times

Having outgrown their first factory, DDS move to their current premises in the village of Portchester, Hampshire on the South Coast of the UK. The new facility, located close to the historic Portchester Castle, enables DDS to expand production significantly and has a footprint which allows for future growth.

Relentless R & D

Development of DDS sensor products number 2 & 3 continues with ongoing R&D directed to CO and H2S. Our commitment to investment in automation begins with purchase of first automated sensor filling robot.

A leap forward in CO Safety

DDS launch a new CO sensor which thanks to simplified design, cost-engineered bill of materials and innovative new production techniques proves disruptive from the outset, quickly gaining market share.

H2S completes the set

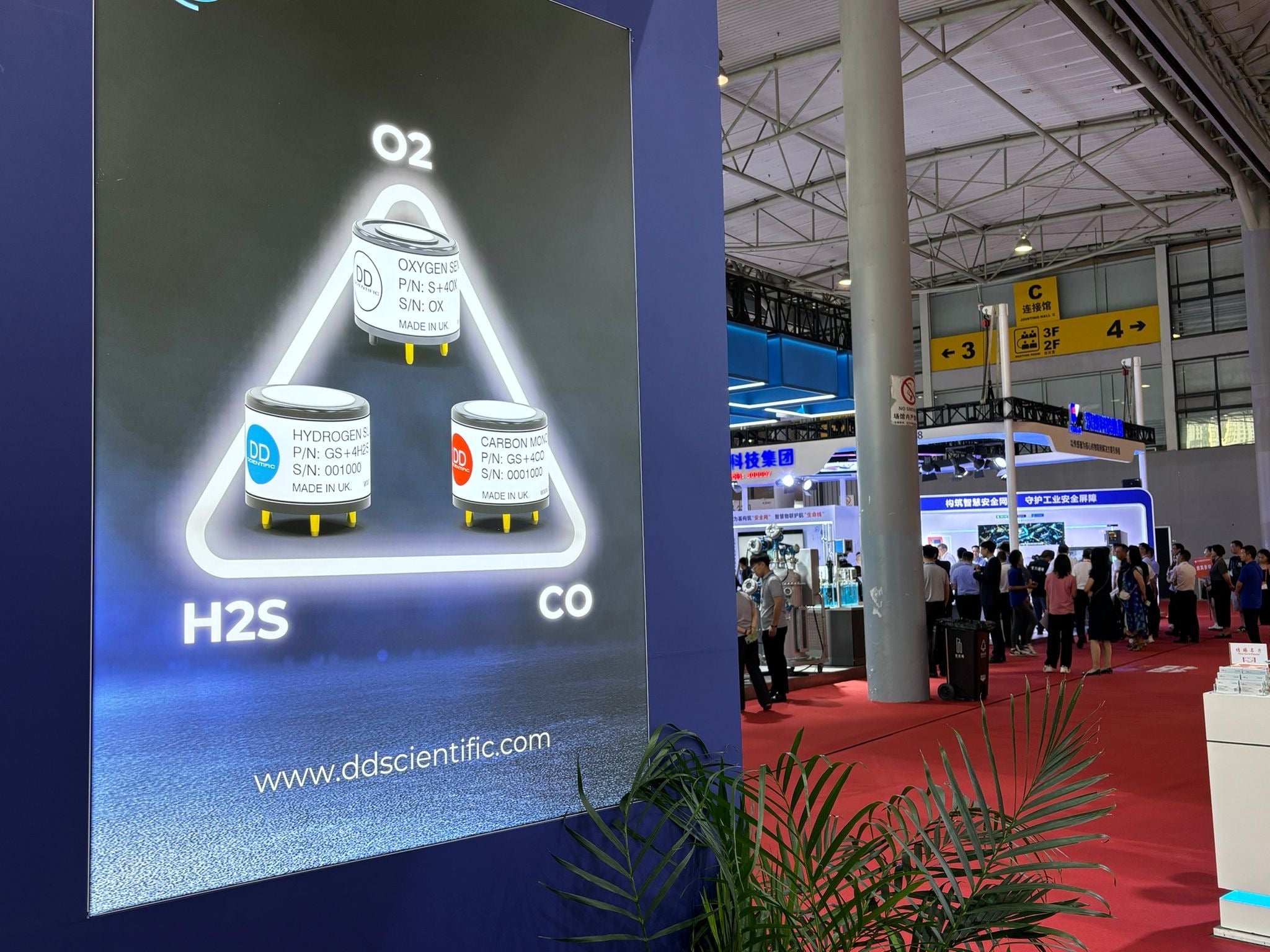

With the launch of an H2S sensor, DDS begin to offer customers the full O2, CO & H2S suite of sensors commonly required in the industrial safety sector. The DDS triple-pack proves popular, gaining market share around the globe.

Automatic for the people

As global demand for DDS sensors increases, significant investment in automation is made to ensure volumes are met and lead-times are optimised. Automation is a critical thread which runs though DDS to this day - driving quality up, keeping cost down and allowing us to deliver in the high volumes the market demands.

Two's company

DDS launch the GS+4DT - the world's first viable dual CO/H2S sensor. Unlike rival sensors, this new design has extremely low cross sensitivity of H2S gas on the CO electrode, providing users accurate readings which are still best in class today.

A step in the White direction

Sensor industry expert Rob White joins as Global Sales Manager, bringing 15 years experience in the global sensor sector with E2V, City Technology and SGX.

Rob's leadership and expertise expands DDS' global reach and drives sales strategy going forward.

Democratising protection from CO

With CO still one of the largest global killer gases, DDS proudly bring to market their low-cost domestic CO range. The range brings instrument manufacturers unparalleled performance and sensor life at a price point which could only have been dreamt of previously.

Silencing the critics

DDS back up their claims by achieving UL approval on a host of CO sensors for domestic applications. UL certification provided 3rd party validation of the performance, safety and reliability of DDS CO sensors and contributed to the downward cost of achieving CO protection in the home.

Alan Rex joins as Operation Manager

DDS welcome Alan to the fold, bringing with him more than 20 years experience in manufacturing spanning the electronics, automotive and medical sectors, Alan's industry knowledge and management experience bolsters DDS' ability to increase volumes and improve quality over the coming years.

Martin Kelly joins as R&D Manager

With more than 20 years experience in gas sensor development at Honeywell (formerly City Technology), Martin is one of the worlds leading professionals in the field of electrochemical gas sensing.

Martin's appointment solidifies the position of DDS in the market and commences the formation of the most experienced team of sensor R&D experts in the industry.

A place in the sun

DDS achieve a major milestone with the launch of the GS+7H2S-DC - the DC suffix denoting 'Desert Climate'. This World first, the result of more than 2 years of testing, brings to market an H2S sensor with extreme resistance to High Temperature and Low Humidity.

Originally developed for the Middle East, the DC has since gone on to excel in the US and Asia also.

Lead-Free O2

DDS launch a pioneering new range of lead-free O2 sensors which offer fast, reliable oxygen measurement without the environmental and health risks associated with lead.

Not only do the new lead-free sensors present OEMs with the first viable alternative to lead but provide other upsides including fast response and sensor lifetime 3 x that of their lead-O2 counterparts. This new innovation from DDS

Congratulations Rob & welcome aboard Terry

After a successful 3 years in the role of Global Sales Manager, Rob White is promoted to the role of Sales Director, joining Daniel on the board and focusing his attention on the continued growth of the business.

DDS are pleased to welcome Terry Moran, an experienced scientist with 25 years experience in sensor development, who joins as Senior Development Scientist. Terry bolsters Martins' R&D team as DDS look to expand their product portfolio and global presence.

Royal Recognition

DDS are awarded the Prestigious Queen's Award for Enterprise in International Trade (Export). The award is presented in recognition of exceptional growth in overseas sales and acknowledges DDS' ability to compete globally and deliver export growth over a sustained time period.

Readiness when it matters most

As the Global Covid-19 pandemic puts pressure on the medical industry to deliver high volumes of life-critical equipment, DDS receive multiple enquiries from ventilator manufacturers who are struggling to meet demand with their existing sensor supply chain.

Using a combination of cutting-edge manufacturing techniques and rigorous internal screening and isolation procedures, DDS deliver! In the space of just 4 weeks, DDS scale up output of their VOX medical O2 sensor from 100 units per month to 4500 per day.

Small in stature, big on benefits

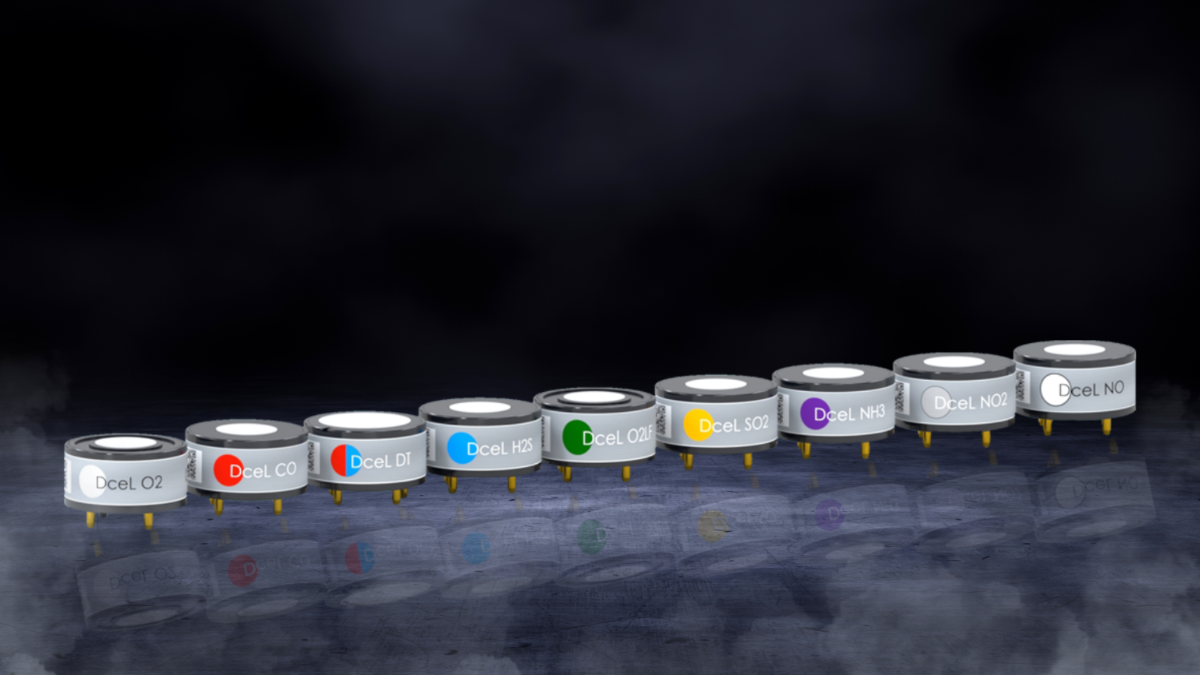

DDS launch the DceL, an innovative new sensor range which shares the same diameter and pin-out as the industry standard 4-series but is 1/2 the physical height, enabling instrument manufacturers to produce ever slimmer products without closing the door on 4-series entirely. The DceL proves popular and goes on to feature in NPD projects with a number of large OEMs.

Testing times

DDS install a state-of-the-art, high-volume automatic test system (ATS), increasing their ability to produce and test high-volumes of electrochemical sensors. This significant investment consolidates existing testing regimes alongside newly created procedures to set a new standard in production quality and future-proof DDS' ability to scale up production.

Alan Rex is appointed Operations Director

Alan, a member of the team at DDS since 2017, joins Daniel and Rob on the board of Directors. Alan's appointment is made in recognition of the positive impact he has had on the business and its products, strengthening DDS at board level and reinforcing their position within the gas sensor sector.

Putting the hammer down

DDS formalise their vision for the Worlds' first fully automated sensor production line under the banner of 'Project Thor'. Whilst the current automation infrastructure at DDS delivers 3.5 x the volume output per employee of their peers, DDS are keen to realise the goal of fully mechanised manufacture where possible,

Oxygen centre officially opens

DDS unveil a new dedicated Oxygen sensor production facility, consolidating 7 production lines manufacturing Lead-O2 and Lead-free sensors under one roof. The opening of this new 8000 ft2 production facility marks a significant milestone in the company’s journey and is testament to the scale of demand for DD-Scientific Oxygen sensors.

Martin Kelly appointed R&D Director

Martin Kelly is promoted to the role of Director of Research and Development. By now with more than 30 years of experience, Martin has played a pivotal role in spearheading the development of DDS electrochemical sensors and driving innovation within the business.

In pursuit of excellence

After 8 years at the forefront of global sales, Rob passes the baton to new Sales & Marketing Director Will Parrett. Formerly of Alphasense and Honeywell, Will brings 20 years experience in the supply of safety critical equipment to DDS.

In parallel to Will joining, Rob transitions into the role of Director of Excellence, a newly created position which sees him channel his extensive knowledge of DDS and its customers in the continued pursuit of world-class quality and manufacturing innovation across the business.

Unlocking digital potential

DDS provide never seen before customer insights with the launch of a series of corporate videos, new interactive website and improved global digital presence, providing customers with easier access to product information and a window into the culture of this rapidly growing business.

PPB Air Quality Sensors

With the launch of its new Air Quality PPB sensor range, DDS provides instrument manufacturers with the opportunity to enhance their product offerings, reduce production costs, and increase the adoption of AQ instruments globally.

Kings Award

Thanks to the dedication and hard work of everyone at DDS, we won the prestigious King’s Award for Enterprise for International Trade. In September, Nigel Atkinson Esq, HM Lord-Lieutenant of Hampshire, visited the factory to present the award.

New ranges

In January, we announced our newest sensor package, the MceL. Compact, reliable, and built for performance, it’s designed to meet the needs of today’s OEMs.

This year we also released our OX-LFF Sensor, with a start-up time of less than 2 minutes from zero power, as well as introducing high-humidity sensor variants and a full medical range.

Whilst we are proud of our achievements to date, the culture at DDS is not to dwell on our past successes but to strive for better.

Every day at DDS brings something new and we have a host of exciting projects in the pipeline, most of which we can't talk about, some of which we can.

Coming soon

- ConnecteDD: the NEW DDS real-time customer interface

- New sensor flavours in existing packages, including new exotics, an extension to our MceL range, PCBs and new sensor technologies

- Performance upgrades to existing sensor designs

⬇️ Sign up to our newsletter below to find out more.