So, what makes DD-Scientific so special?

We are proud to do things differently at DD-Scientific, something which is valued by our workforce and customers alike.

⬇️ There are many reasons why customers are switching to DDS, just some of them are listed below.

Whether you need sensors for run-rate production, projects, prototyping, NPI or spares - you need to know you are working with reasonable lead times.

We know that when lead times are long, they slow your ability to deliver, to grow and to evolve.

What are DDS' lead times?

- Typical lead time on 1000 sensors is 2-3 days*

- Typical lead time on 10,000 sensors is 2-3 weeks*

- Fluctuations in demand can be met at short-notice

* applies to the majority of mainstream sensors - some models have extended stabilisation times which may extend this lead time by a period of 1-2 weeks.

The DDS difference

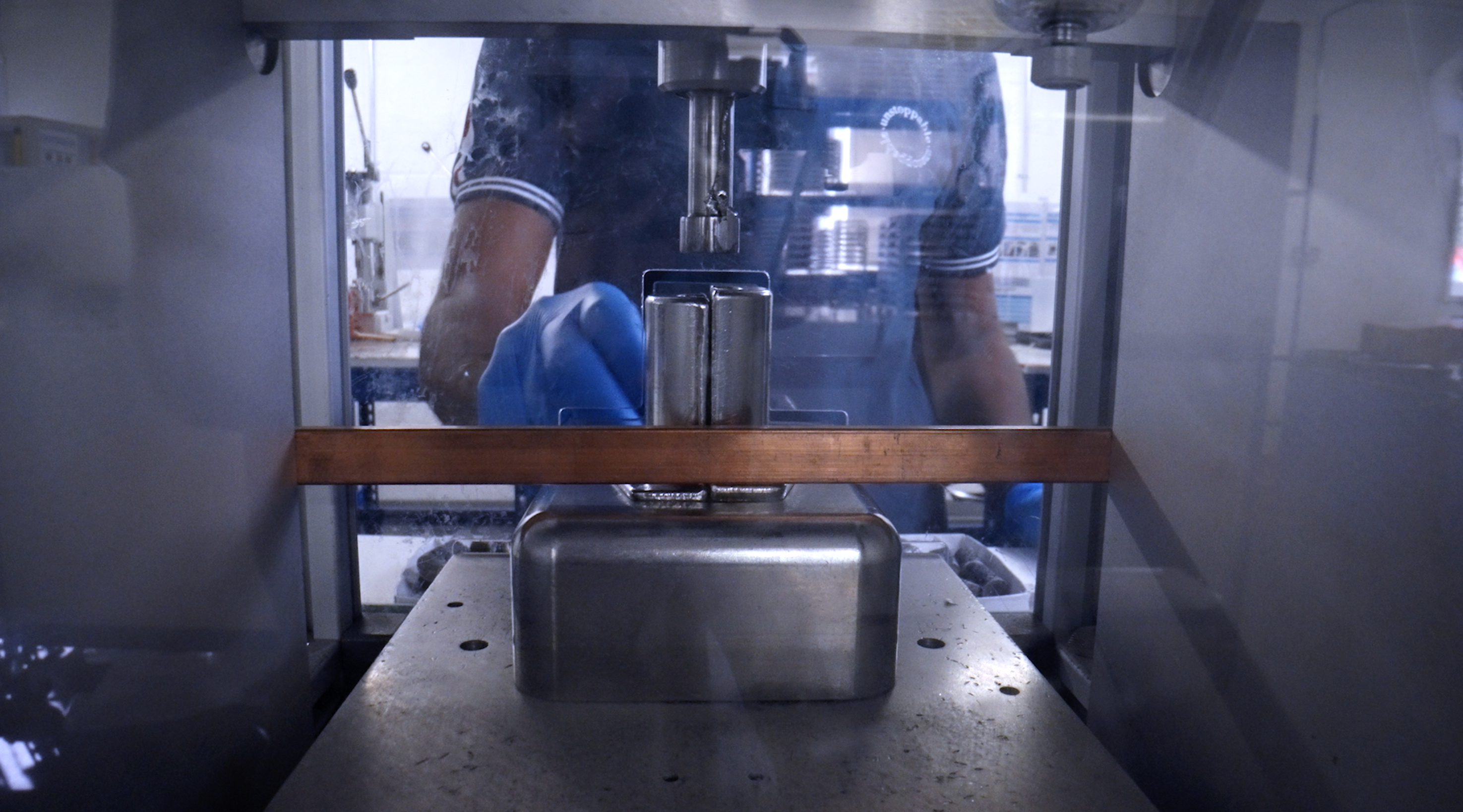

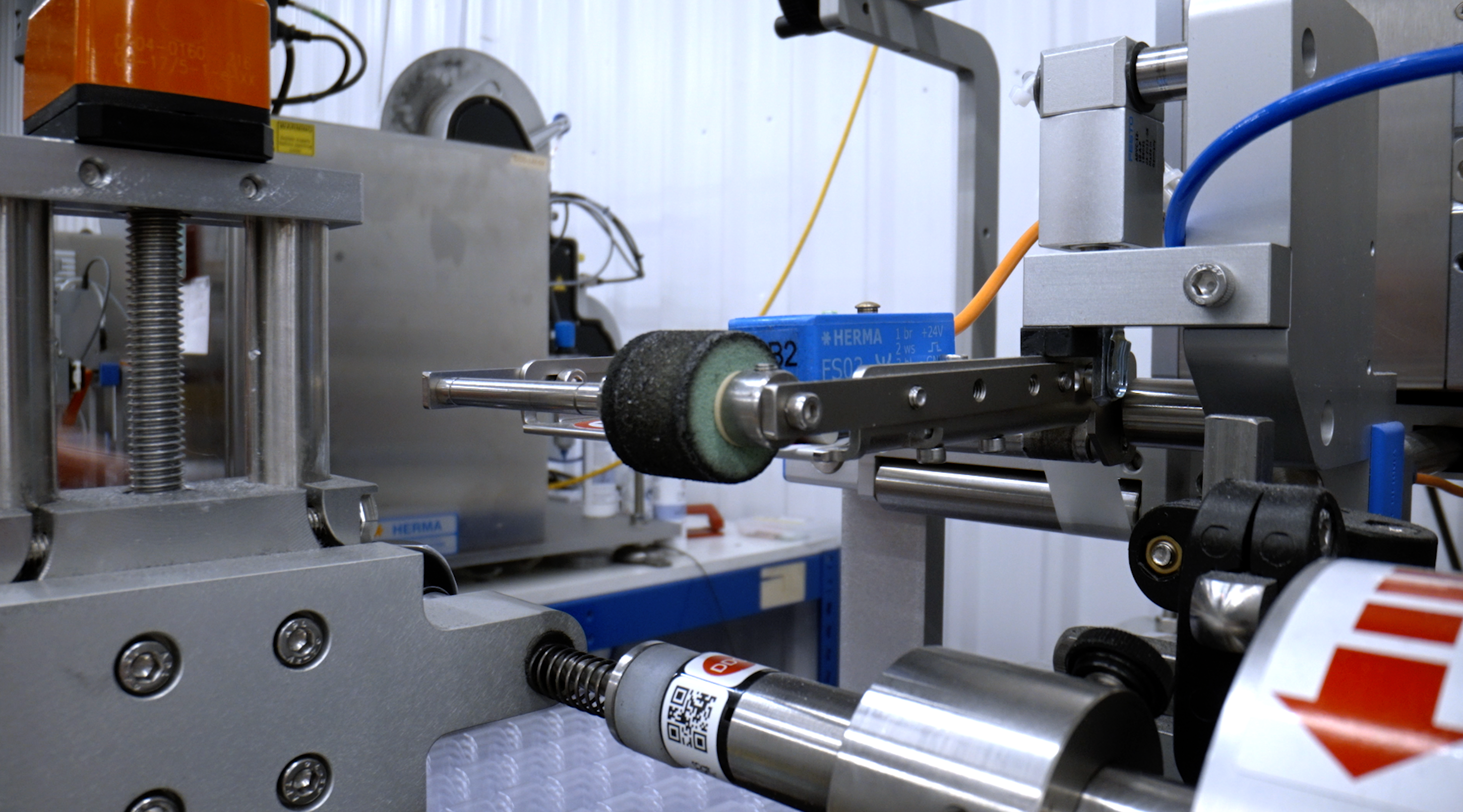

After many years of investment in cutting-edge manufacturing, our UK-based sensor production facility is now the most advanced on the planet. Not only do we produce high-quality sensors in greater volumes than any other manufacturer, but our output is repeatable, consistent and scalable.

Where other manufacturers look to increase output by relocating production to less regulated low-cost regions, we take an 'automation not relocation' strategy which delivers a stable and lean manufacturing base.

Whether your preference is Kanban, call-off, scheduled shipment or spot-order, we will meet and frequently exceed your expectations.

Unexpected delays in sensor deliveries impact your production schedules, limit your ability to ship product and disrupt cash flow.

We appreciate that repeat occurrences damage reputations, drive unplanned discounts and eat up administrative time.

Where do DDS stand on OTD?

98% on-time delivery (based upon customers' requested ship date).

We'll never 'bump' your order to satisfy another customer.

The DDS difference

We pride ourselves on our ability to deliver on time and we keep our customers informed throughout the purchase process.

We hold ourselves to account by basing our on-time delivery metrics upon customer expectations rather than our own.

Cutting-edge paperless production systems and integrated ERP help us schedule work and ensure that shipments are not delayed or missed.

With our upcoming connectedd offering, customers are provided with a window into their shipments, with the ability to track order status to individual sensor level in real-time.

End of line failures reduce your production yields and cost you money. Reduced yields impact lead times, customer relationships and ultimately the price you can achieve for your product.

When latent T90 issues occur, they typically present themselves either during instrument calibration or worse in the field when the end-users life depends upon your instruments.

At DDS we appreciate how instrument failures can destroy instrument reputation and cause irrevocable damage to brand perception.

How quickly do DDS sensors respond?

DDS T90 times are typically as fast as our peers and frequently better. In the case of O2 sensors, T90 is guaranteed to be <10 seconds and is typically <5 seconds.

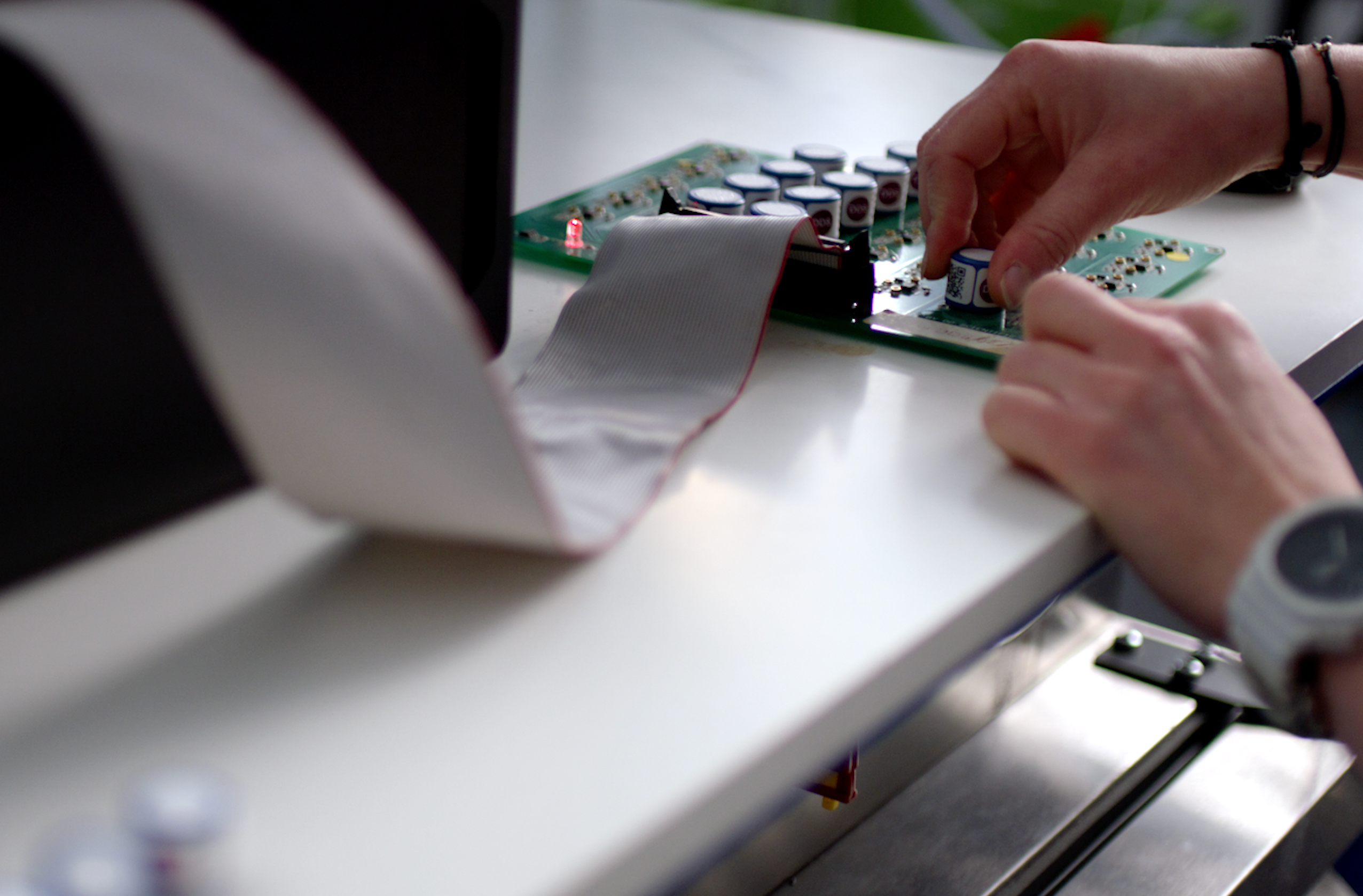

Each and every sensor we produce is fully tested prior to despatch to ensure compliance with its respective data sheet.

The DDS difference

Our R&D team now boasts more than 75 years collective experience in gas sensor design and development. It's this experience which drives continuous advances in our sensor technology. An example of our product superiority is our lead-based O2 sensor which has a response time at least 35% faster than other manufacturers.

Our bespoke automated test system (ATS) put sensors through a rigorous test procedure prior to despatch, ensuring DDS sensors perform as we say they will. This practice applies to every sensor we sell and unlike other manufacturers, we will never relax our quality standards in order to meet targets.

We know that end users expect increasingly more value for money from their instruments and the last thing manufacturers need is high-cost sensors driving up BOM cost.

How do DDS compare on price?

DDS sensors typically offer customers at least a 25% cost reduction over other manufacturers.

The DDS Difference

DDS sensors are engineered to be fit for purpose and designed for automated production. This means less material usage, reduced labour costs and a low scrap rate - savings we pass onto our customers.

We take a pragmatic approach to pricing which ensures our OEM customers remain competitive and supports growth in the important industry sectors we serve.

When suppliers impose repeated or unexpected price increases on OEMs, they drive up manufacturing costs and make it difficult to manage distributors and end users, especially when the frequency, notice period or terms are unreasonable.

Where do DDS stand on pricing?

Whilst we aren't immune to price increases, we don’t have an annual price rise cycle & we only increase prices when absolutely necessary to maintain a reasonable margin.

If prices do increase we will provide at least 8 weeks notice and will guarantee pricing for a period of minimum 12 months.

The DDS Difference

For many of our customers, pricing has remained consistent for a number of years. In some cases, pricing has reduced in line with increasing volumes.

At DDS annual Sales growth is achieved by selling more sensors to more OEMs - not by imposing price rises on our existing customers.

To maintain our margins we work hard to counter increases in raw material and utility expenditure by delivering savings in manufacturing costs. With this approach we do our best to absorb increases in base costs rather than simply imposing price increases on to our customers.

When a supplier wants you to jump through hoops to get things done it makes your life difficult. Lengthy processes, unnecessary documentation and unreasonable terms increase your costs and divert time from your core business.

As companies grow they typically become less flexible in satisfying customer need.

How is the DDS approach different?

At DDS, one of our core values is to make our customers lives easier and for that reason we look to accomodate customer requests as long as they are reasonable and both financially and strategically viable.

The DDS Difference

Whether its custom products, private labelling or long term supply agreements which work for your business, we will do our best to make it happen.

With no external approval channels to navigate our approach is simple - if a request makes sense for both parties, we will do our best to make it happen.

We also do our best to keep bureaucracy to a minimum, reducing the workload on our customers and making us easy to do business with.

We know how critical sensor supply is to our OEM customers and the importance that high-quality customer service plays.

When manufacturers implement cost-cutting measures it frequently has a negative impact on customer service. Expense reduction in the form of factory relocations, site closures and periods of forced leave limit production capacity and cause interruptions in supply chain.

Where do DDS stand on service?

Customer service is at the forefront of everything we do and is an area where we truly differentiate ourselves from our competitors.

DDS operate from our UK based, wholly owned manufacturing facility where we continue to invest heavily in people, processes and automation.

Whilst we are one of the worlds leading sensor manufacturers, we retain the ethics, values and atmosphere of a family business.

The DDS Difference

Our responsible approach to financial management negates the need for short term 'cost-saving' measures and allows us to keep customers front and center.

Whilst we are always look for opportunities to make saving as we expand, we aren't willing to compromise our customer experience in pursuit of incremental savings.

When a supplier promises new products but doesn’t deliver, they compromise your ability to progress as a business.

Effective NPI relies upon suppliers remaining at the forefront of sensor technology.

Where are DDS on innovation?

With a short NPI process and an agile business structure, we can react quickly to industry trends and to customer requirements.

Our portfolio has grown significantly in recent years and is due to increase further with the planned introduction of more than 25 new sensor models/varients over the next 12 months.

The DDS Difference

We are proud to employ some of the best in the business at DDS, not least in the field of product development. Our position as the fastest growing sensor supplier globally is reliant upon us driving innovation through cutting edge manufacturing and frequent delivery of new sensor variants.

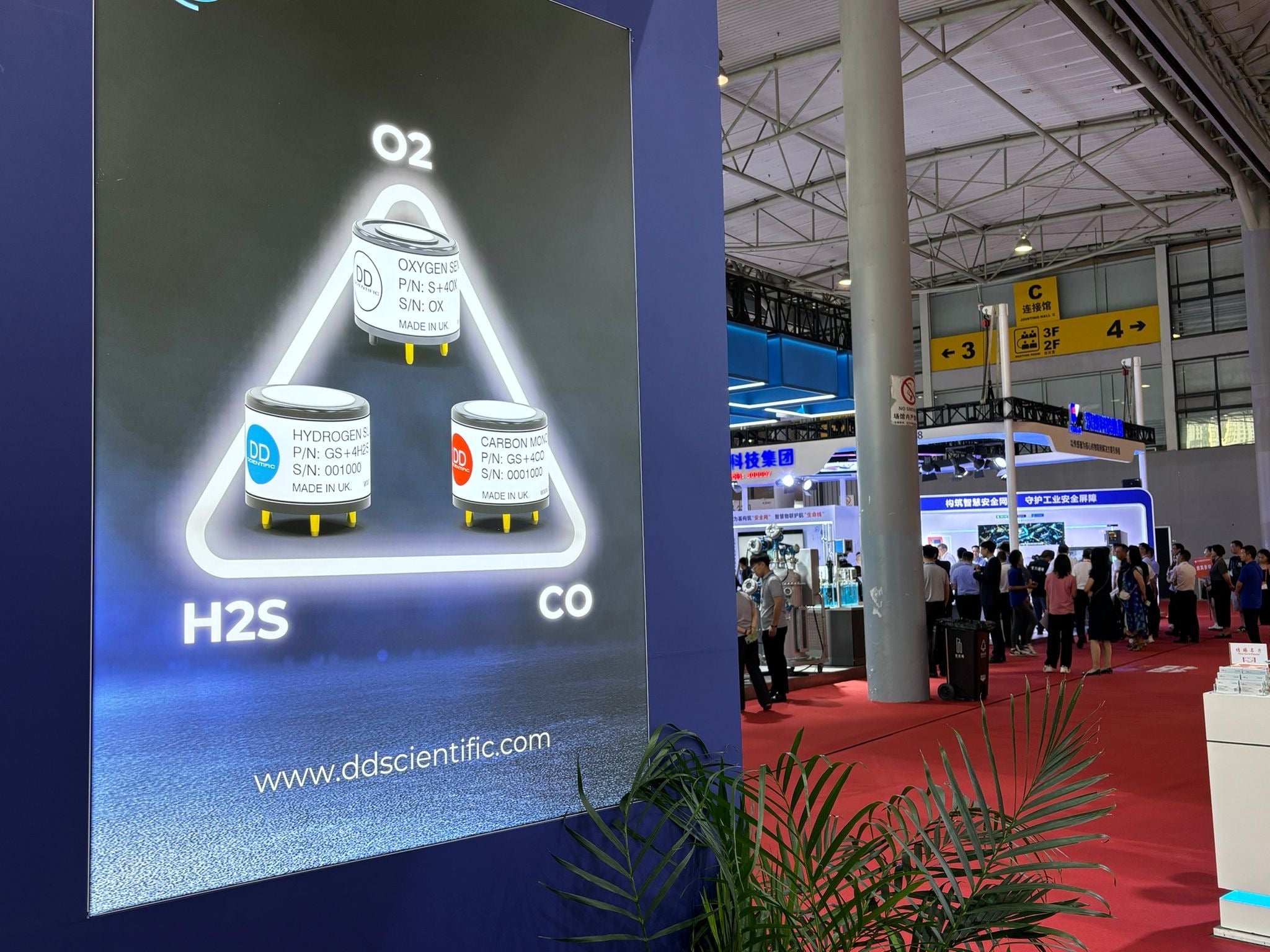

DDS O2 sensors are increasingly the first choice for instrument OEMs. With the fastest lead-based O2 sensor on the market and a best-in-class lead-free O2 sensor alternative, DD-Scientific produce more O2 sensors per year than any other manufacturer.

When you want to scale up your production, you need a supplier who can meet your demands. When sensor manufacturers rely too heavily upon manual labour or have limited capacity for expansion, it holds OEMs back.

When working with a supplier who can't scale up, an OEM's ability to be fast to market is compromised and growth is limited to the pace of the suppliers own expansion.

What do DDS have to offer?

Automated manufacturing makes for simpler and quicker ramp up / down of production.

With a typical annual growth rate of 30%, every process or procedure at DDS is developed with scalability in mind.

The DDS Difference

At DDS, we produce more sensors per year than any other mainstream manufacturer. The growth we have achieved since we were founded in 2011 has been reliant upon our ability to scale-up production to meet the demands of our growing customer base.

Perhaps the best example of our scalability is our delivery of O2 sensors to the ventilator sector during the Covid 19 epidemic. In the space of just 4 weeks, we scaled up output of our VOX medical O2 sensor from 100 units per month to 4500 per day.

Sourcing through distribution can be slow, expensive and frustrating. The absence of direct communication with component manufacturers frequently makes for a disjointed and frustrating customer experience.

Many OEM gas sensor distributors also supply instruments in direct competition with their customers - a clear conflict of interest.

When OEMs are forced to buy their sensors through distribution they lose freedom of choice and become disconnected from vital resources such as tech support and R&D.

Where can I buy DDS?

We deal direct with our customers, providing them with the benefit of;

- Direct access to technical support

- Clear communication around order status, lead times, stock levels etc.

- Direct contact with R&D team, be it for customisation, product feedback or future forecasting

- Better pricing than through distribution

- No conflict of interest with instrument supply or concerns around confidentiality

The DDS Difference

DDS is built on the basis of strong customer relationships and as we grow we are investing in building these relationships further and wider. Aside from the obvious benefits that dealing direct brings to our customers, we believe that regular interaction keeps us tuned into the needs of our customers and ensures we stay at the forefront of innovation.

Working directly with customers negates the need for distributor margin and gives our customers the best price proposition available.

Additionally, the combination of our direct to market strategy and rigorous pricing controls allow us to manage our route to market more effectively than other manufacturers, enabling us to avoid conflict and protect customers' margins.

There are no customers too big or too small for DDS. Put simply - we value our customer relationships too much to pass them on to 3rd parties.

Switching to a new sensor supplier can be problematic for OEMs, especially when they are historically tied to a sensor brand.

Sensor changes can take time, effort and money, resources instrument manufacturers rarely have to dedicate to legacy devices.

OEM reluctance to leave a legacy sensor supplier can lead to those suppliers taking that customer for granted, reassured by the perceived complexity of them switching to another brand.

How do DDS make switching easier?

We manufacture a broad range of sensors in commonly used formats meaning we can nearly always offer OEMs an alternative.

Many of the sensors we make are drop-in replacements for other manufacturers which require no hardware changes to instruments.

If we don't make an interoperable sensor we will consider doing so if there is demonstrable demand.

We offer extensive technical support to ease the process for our customers, including support with recertification and direct access to our R&D and electronics specialists where required.

We typically save our customers more than 20% on their sensor spend.

With a typical saving of more than 20% on their sensor spend, customers who switch to DDS frequently cover the cost of switching in months rather than years.

The DDS Difference

There are many reasons why customers are choosing to switch to DDS but fundamentally we offer a better value proposition.

DDS are renowned for excellent customer support, responsive service and technical expertise that ensures seamless integration and ongoing success with their sensors.

Our combination of innovative technology, dependable performance, and a strong focus on customer satisfaction makes DDS the logical choice for OEMs seeking a reliable and forward-thinking sensor supplier.

We have a long track record of winning business from our competitors and we will be happy to provide trade references to anyone considering doing business with us in the future.

Making the switch to DD-Scientific

If your current gas sensor supplier isn't treating you right we should talk.

1️⃣ Our first step would be to review your current sensor specifications in order to recommend the DDS alternative and provide volume based pricing. We have done this many times so it is a quick process for us.

2️⃣ Once we understand your needs we will make our recommendations, clearly outlining any technical differences which may impact your instruments. In many cases, the DDS equivalent sensor will be a drop-in replacement which requires no hardware changes to instruments.

3️⃣ Even where minor changes or recertification are required, we are confident that your cost-benefit analysis will favour DDS.

4️⃣ When you are ready to proceed, we will be glad to lock-in long term pricing and optimise order processing and lead times to suit your production requirements.

Throughout the process the DDS team will work with you to provide full support with;